Inspection of API manufacturers: First Results of the WHO Pre-Qualification Programme

Last autumn, the WHO started a programme for the pre-qualification of APIs which completes the already existing pre-qualification programme for medicinal products (see our News vom 28 October 2010). The aim of this programme was to assure the high quality of APIs and medicinal products destined for the use in third world countries especially. It covers APIs for the manufacture of pharmaceuticals against HIV/AIDS, Malaria, Tuberculosis, Influenza, pharmaceuticals for reproductive health as well as zinc sulphate.

The WHO has recently published a Newsletter where it describes its risk-based approach of API inspections and presents a set of statistics based on both inspections which have already been performed and on upcoming inspections.

Basically, the following conditions prevail for the pre-qualification programme (PQP):

- All the APIs for the diseases and applications mentioned above should be covered by a PQP inspection.

- In any case, the GMP Compliance of the API manufacturing site must be confirmed every four years.

- The WHO inspections are performed based on the ICH Q7 guidance.

A PQP inspection is not necessary in following cases:

- When within the past two years, a successful inspection has been performed by a recognised organisation (e.g. EDQM, authorities from the PIC/S Member States or the FDA).

- When the API manufacturer submits to the WHO a copy for review of the last performed inspection within the PQP framework and this review is successful.

Independently from the cases mentioned above, the WHO reserves itself the right to perform an inspection anytime based on risk considerations.

The WHO Newsletter contains interesting information about inspection statistics:

- 126 API manufacturers participated in the PQP. Most of the sites are located in India and China.

- 49 of them have been listed as GMP-compliant because of previous authority inspections.

- 31 have been inspected by the WHO.

- 6 failed the inspection because of missing GMP compliance.

- The remaining sites haven't yet been inspected.

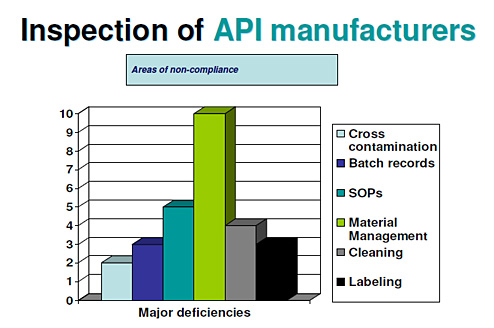

Also interesting is the presentation of the most frequent GMP deviations: the front runners are deviations in equipment management and documentation as well as insufficient cleaning. The following chart illustrates the frequency distribution of GMP deviations:

Please also see the WHO Newsletter.

Author

Dr Gerhard Becker

CONCEPT HEIDELBERG (a service provider entrusted by the ECA Foundation)

Conference Recommendations

Related GMP News

GMP Conferences by Topics

- General Quality Assurance and GMP Compliance Topics

- Hygiene

- General Microbiology Topics

- Regulatory Affairs

- Development

- General Analytics Topics

- Good Distribution Practice

- Sterile Manufacturing

- Computer Validation

- General Qualification/Validation Topics

- General Engineering Topics

- APIs/Excipients

- GMP Basic Training Courses

- Medical Devices and Combination Products

- Packaging and Packaging Material

- Data Integrity

- Qualified Person (QP)

- GMP Auditing

- Documentation

- Cleaning Validation

- General IT Compliance Topics

- Impurities

- OOS / OOE / OOT

- Material Testing

- Validation of Analytical Methods

- Analytical Instrument Qualification

- Stability Testing

- Microbiological Testing

- Technology

- General Manufacturing Topics

- Solid Dosage Forms/Semi-Solid Dosage Forms

- Biotechnology/Blood/ATMP

- Herbal Drug Products/Cannabis/Radiopharmaceuticals

- Others